Company Details

Location

Santa Fe, New Mexico

Founded

2006

Ownership Type

Public

Employees

12 full-time; up to 6 consultants

Products

3D metal printing software

Santa Fe, New Mexico

Founded: 2006

Publicly traded (OTCQB: SGLB)

Employees: 12 full-time; up to 6 consultants

Industry: Industrial & Equipment, Contract Manufacturing

Products: 3D metal printing software

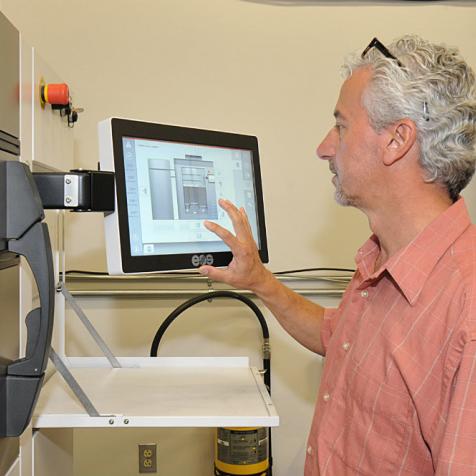

By bringing quality assurance to 3D metal printing, CEO and co-founder Mark Cola is helping catalyze a nascent industry.

Three-dimensional printing is transformative technology with the ability to manufacture articles within microns of tolerances, and it is changing the way that companies prototype, produce and manufacture.

With applications in the aerospace, energy, and medical industries, 3D metal printing allows engineers and designers to develop products in ways that milling, machining, or forging can't match. In addition, it can make parts more rapidly and with little to no need for tooling and with little to no waste.

"As people have learned about the 3D metal printing industry and the promise it holds, what they've realized is that the enabling technology that allows them to move from 3D metal printing to additive manufacturing just isn't there," explains Cola. "That's the gap that exists today that Sigma Labs' technology is bridging. The gap between 3D printing, which is prototyping making one- or two-off sort of articles, versus additive manufacturing, which is more massive or serial production."

The PrintRite3D sensors and software that Sigma Labs, itself a 3D metal printing company, is offering provide third-party quality assurance or what Cola says is known as objective evidence of compliance back to the design intent. In real time, the process verifies that the article printed matches the original design.

"The question is: 'How can you reduce your reliance on post-process inspection such that I now can combine my manufacturing step with my inspection step and make it one step instead of two?'" says Cola. "That's what our software allows people to do. . . . By adding quality assurance to the manufacturing process, PrintRite3D can help companies realize considerable gains in cost reductions. That way the user can make an immediate decision whether or not a printed article should be allowed to go on to other stages of production, adding value to it or be set aside for future inspection."

He adds, "That is a paradigm shift away from traditional manufacturing where people make in one step and inspect it in another. We're giving them the tools and methodology to combine it into one step."

It's also helping regulatory agencies like the FAA and FDA accept products or pieces made via additive manufacturing, he adds. "As long as they can feel comfort with the fact that there's objective evidence of compliance and assurance of the quality across the supplier base."

The company is currently beta testing its software in North America and Europe with about a dozen companies, according to Cola. Among them are companies like General Electric, Honeywell, Siemens, Stryker, and Additive Industries, a 3D metal printing company that's investigating incorporating Sigma's technology into its machines.

The company is gaining information from its beta testers and hopes to launch the license-based platform by early 2018. "We've got two programs right now available to our customers depending on what type of customer they are. Our efforts are focused in two areas, the OEMs that make the 3D metal printers and the early adopters that are the end users that use this type of technology," Cola explains.

Challenges: "How quickly the industry can move to adopt these technologies and make that paradigm shift from inspecting in separate steps as opposed to combining them with the manufacturing step," Cola says.

Opportunities: "We see ourselves complementary to what's happening with the whole industrial Internet of Things," Cola says. "We're helping take the Big Data problem and reduce it down to a manageable level such that we can port this data into the cloud, run real-time analysis on it, then export this data back down to the operator."

Needs: "We've announced that we're in an effort to take Sigma Labs from the penny-stock arena and into the NASDAQ," says Cola. "At that point, we will have brought it to a wider investor base that we believe will ultimately benefit the company."