KMLabs

By Eric Peterson / CompanyWeek | Jan 18, 2016

Company Details

Location

Boulder, Colorado

Founded

1994

Ownership Type

Private

Employees

20

Products

Lasers

Boulder, Colorado

Founded: 1994

Privately owned

Employees: 20

Fresh off a $5.5 million investment led by Intel, the cutting-edge laser manufacturer is bringing innovative new products to the biomedical and electronics industries.

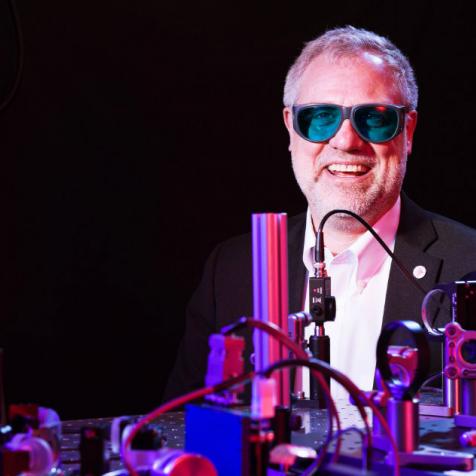

Henry Kapteyn and Margaret Murnane are the husband-and-wife K and M in KMLabs. The company grew out of their research that started in the early 1990s at Washington State University. "One of the first things we accomplished while we were there was developing a laser that could create very, very short light pulses," says Kapteyn.

These pulses can be shorter than 10-14 seconds, or 10 femtoseconds. To put it in perspective, a single femtosecond compared to a minute is the same ratio as a minute is to the age of the universe.

"We developed a very simple laser that could do this," says Kapteyn. "The very short pulse duration makes it possible to generate light pulses with very high peak power, since power equals energy divided by time. Peak power of 1 terawatt is possible -- a number greater than the total US electrical grid capacity."

Kapteyn and Murnane's initial attempts to commercialize the technology reaped small successes, but the concept soon caught on strong in academic settings. "It was the highest performing laser for researchers working at the cutting edge," he says. "Now these things are ubiquitous."

Kapteyn and Murnane moved to Boulder and CU and brought KMLabs along in the late 1990s. "We decided it was a good enough entrepreneurial environment to make this a real company instead of a basement operation," says Kapteyn. The company hired its first employee in 2000 and grew quickly from there.

The technology has changed over the years. Short-pulse X-ray lasers were developed with the Star Wars defense program in mind in the 1980s, and the thought back then was that they'd run on nuclear power. "It's no problem if an atomic bomb is powering it," Kapteyn explains.

But smaller scale means lower power requirements. "We're essentially making something that's like a tabletop X-ray laser now," says Kapteyn. "It's much more practical. It still plugs into the wall." The concept "is quite new," he adds. "It's just now reaching practicality."

Components are sourced from all over the world and assembled in Boulder, and a lot of the work is custom. "Since we're kind of at the top of the food chain for laser construction, we buy a lot of finished components," says Kapteyn, calling the company "a systems integrator" with machining capabilities. "We purchase worldwide."

KMLabs’ lasers start at the "tens of thousands," says Kapteyn, but can sometimes sell for more than $1 million. "We're doing some very expensive, high-end lasers."

After initial assembly and testing, the lasers are disassembled, shipped, and reassembled by a KMLabs team at the customer's location. Kapteyn says the company sometimes has teams on three continents at once.

The company sells into about a dozen countries. "Germany is our single biggest market," says Kapteyn. "The U.S. isn't paying much attention to lasers at the moment."

Research remains the biggest overall market and startups are also big buyers, and medical devices are a target market.

Semiconductor testing is another relatively new market for KMLabs, and it looks promising. It follows that Intel Capital recently led a $5.5 million Series A investment round in the company. The Colorado Impact Fund also participated.

"Moving forward with Moore's Law charging away . . . [Intel] need to use shorter wavelength light," Kapteyn explains. "They know they need solutions."

Challenges: "We're doing a very complicated technology with a relatively small staff," says Kapteyn. "It's also a challenge for us to have a worldwide market. Research is becoming a worldwide phenomena."

Opportunities: "There are big market opportunities still in the research area," says Kapteyn. Beyond the growth potential in semiconductor testing and measurement, nanoscale imaging and surgery could be big medical uses, he adds. Another is "a new type of microscope" for use in nanotechnology manufacturing, he adds. "People have not been able to image small structures with these wavelengths in the past."

Needs: Talent. "We're going to be growing to go into these new markets," says Kapteyn. "So we'll need more good laser people. Eventually we'll need more funding. Ramping up will probably require a second round of investment."