Company Details

Location

Montrose, Colorado

Founded

2014

Ownership Type

Private

Employees

6

Products

Tanks and brewing systems

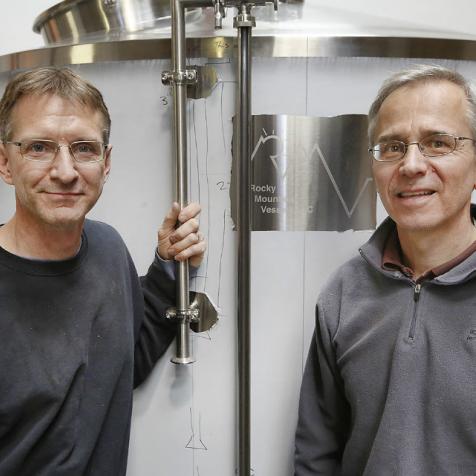

Co-founders Darin Houtstra and Ralph Stellmacher look to make simple, efficient, and affordable equipment for small breweries.

After the Ridgway residents met through their wives and same-aged daughters, Houtstra and Stellmacher became fast friends and then co-founded a manufacturer.

"My background is in finance, Darin's is in fabrication," says Stellmacher. "Getting together just made a lot of sense."

Houtstra's experience led him to come up with a number of improvements and innovations for brewing tanks. "I saw an opportunity in the market," he says.

Case in point: The duo went to BrewExpo America in 2014. "We're looking at all of the equipment and what we found was fabricators seemed to be very focused on equipment that was very expensive and catered to brewers with very large budgets," says Stellmacher.

In contrast, they launched Rocky Mountain Vessels to make "simple, efficient, and affordable” brewing equipment, he adds. "Since we're focused on selling to younger breweries, startups, and breweries with small budgets, our focus tends to be on equipment that's seven to 15 barrels in scale."

Stellmacher points to Wooden Hill Brewing Company in Edina, Minnesota, as an example. "They bought a typical brewing system from us," he says. "It's very easy to use, it's very efficient, and it's affordable. One person can operate the system."

Adds Houtstra: "We believe the direction the craft brewing industry is going, it's not going to be big production breweries, I think it's going to be scaled back. It's going to be small, mom-and-pop breweries. There's just limited shelf space."

The market agrees. Rocky Mountain Vessels has sold equipment to more than 60 breweries from Maine to Washington State. Colorado-based customers include Lone Tree Brewing, Crystal Springs Brewing, and Holidaily.

Growth "has been exponential," says Stellmacher. "We're averaging 20 to 25 projects a year."

It all comes back to Rocky Mountain Vessels mantra of "simple, efficient, and affordable," says Stellmacher. While larger systems from other manufacturers can easily run $250,000, Rocky Mountain Vessels’ price tag is notably lower. "For a simple seven-barrel system, we're talking in the neighborhood of $30,000 to $35,000," says Stellmacher.

Houtstra's method starts with the question, "How can I change it to produce a high-quality piece of equipment at a lower cost?" His answer: "You start experimenting."

He highlights some of his innovations: a simple flow manifold, a modular design, and removable false bottoms. "You can pull it out with one hand," he says. "Usually, those are really heavy."

"One of the things brewers talk about is efficiency in the brewhouse," says Stellmacher. "Mash efficiency is something brewers are really fixated on. Our mash tun has a proper aspect ratio for extracting maximum sugars." Multiple drains on larger tanks allow brewers "to pour as much sugar as possible out of that wort," he adds.

Rocky Mountain Vessels started using a CNC welding system in 2015. The result is precise dimple jackets on the tanks that transfer heat more efficiently. "Because it's computer-aided, the likelihood of any flaw goes way down," says Stellmacher.

The reduced human touch also makes for cleaner tanks. "These tanks are extremely sanitary internally," notes Houtstra. "I don't think a lot of brewers realize the importance of that."

Favorite beers: "My favorite beer is anything brewed with citra hops," says Houtstra. "A citra IPA is at the top of the list."

"I'm not as finicky as Darin is," says Stellmacher. "I'm always trying something new. What I haven't tried, I want to try."

Challenges: Awareness in the market. "The biggest challenge still is we're not well-known in the industry," says Houtstra.

Opportunities: Beyond the bread and butter of neighborhood breweries, distilleries and wineries are targets. "That's one of the opportunities we see: to be able to expand into related beverage markets, including distilling," says Stellmacher. Rocky Mountain Vessels recently sold a mash tun to Dry Land Distillers in Longmont.

Stellmacher says they also have plans to apply the company's expertise with stainless steel to another as-yet-undisclosed industry.

Needs: More elbow room. The company started up in a 2,000-square-foot facility in Montrose, then moved to a 4,000-square-foot shop in 2016. "Space continues to be an ongoing challenge," says Stellmacher. The insourcing of cylinder rolling cost the company some production space, he says, and there are plans to bring invest in a waterjet as well, "but that's more floor space."

Houtstra says talent is another need. "More skilled employees is a need coming up," he says.