Reata Engineering

By Eric Peterson / CompanyWeek | Nov 02, 2015

Company Details

Location

Englewood, Colorado

Founded

1993

Ownership Type

Private

Employees

50

Products

Machining services

Englewood, Colorado

Founded: 1993

Privately owned

Employees: 50

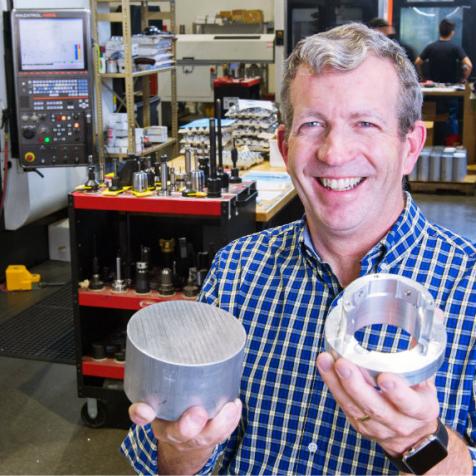

President and CEO Grady Cope has grown his machine shop from a one-man side job to one of the most innovative manufacturers in the region.

While working as a product development engineer for Gates Corporation in Denver, Cope bought some equipment and taught himself how to machine nights and weekends.

"I bought a manual mill and a manual lathe for $6,000 on my credit card," he says of Reata's modest beginnings. "I learned how to be a machinist."

A year later, in 1994, he got some sage advice: Quit your day job and focus on Reata full-time. He followed it and he's since grown his shop to 50 employees and invested in automation.

"I wasn't a really good fit for the corporate world," he says. "It was time to start something else."

But he didn't burn any bridges. Gates was his biggest customer at the outset, then he moved from the rubber giant to semiconductor equipment and contract work for other job shops. Today Reata has a customer base that's primarily in the medical device industry, as well as some aerospace and optics accounts.

It's also got its own brand: In 2000, Cope bought the manufacturer next door, The Cone Mounter Company, and Reata has made bearing heaters under the Cone Mount brand ever since. "It’s a good little business to have tacked on," he says. "We've got customers in Vietnam we ship to regularly. It's a pretty broad-based market."

Growth was fast and furious from the outset, but leveled off in the 2000s. "In 2009 at the worst of the recession, we were at 13 people," Cope notes.

Now Reata is booming again and the staff has quadrupled from the low point. "Since 2009, we've been averaging 30 percent growth per year," says Cope. "It's been huge."

He says investing in advanced technology and sales has been critical to the growth.

Reata's 25,000-square-foot facility is divided into two sides. "The left side of the shop is all automated," Cope says. "The right side is on vertical mills and 2-axis lathes."

"We've gotten really good at adding automated and advanced equipment to our shop for low-volume, high-mix parts," he adds. "That's going to stay in the United States. We're good at it."

Since the company has added automation in 2011, throughput has increased by 50 percent or more. "The automated equipment helped us train our existing workers and get more out of them.

But it's about more than manufacturing automation, he's quick to note. "We're a customer service organization. That's where we need to excel."

Challenges: Hiring. "We've got to work with the schools to educate people," Cope says. "It's a career and it's a really good career." To this end, Cope is active with the Colorado Advanced Manufacturing A locally and served as chairman of the National Tooling and Machining Association, and he sees progress. "We're in the early stages," he says. "People are paying attention. I'm starting to see more youth -- we want more Millennials."

"Manufacturing's cool -- it's really cool," Cope adds. "It's almost like a real-life 3D videogame happening in front of you."

Opportunities: Exporting Cone Mounts. "We focused a ton on Europe and now it's starting to happen," says Cope.

Reshoring manufacturing is another opportunity. "Manufacturing's back," he touts. "The dollar might be strong but it won't stay that way. The United States has become a lower-cost alternative for manufacturing. . . . It's back and it's not going to leave."

Needs: After investing more than $3 million in capital equipment since 2011, Cope is planning to continue to invest in more automation, more multitasking, "and more training with the existing employees" in 2016.

[Nominate a manufacturing ‘game changer’ like Reata Engineering as part of the Colorado Manufacturing Awards. Here’s more information.]