Ophir Optronics Solutions

By Eric Peterson | Aug 16, 2015

Company Details

Location

North Logan, Utah

Founded

1978

Ownership Type

Public

Employees

480

Products

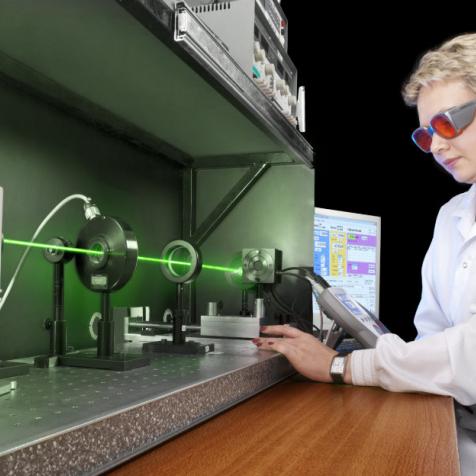

Global leader in laser measurement, precision IR, and laser optics

North Logan, Utah

Founded: 1978

Owned by Newport Corp. (NASDAQ: NEWP)

Employees: 480 (72 in Utah)

GM Gary Wagner is driving the worldwide leader in laser sensing and calibration to big growth with its innovative and industry-leading products.

Founder Carlos Roundy started the company in his hometown of Logan. He had invented laser-based sensors at Bell Labs, but "Bell didn't want to commercialize," says Wagner. But the R&D entity let him spin it off into a separate company, then known as Spiricon.

Roundy's technology was "looking at measuring the characteristics of a laser beam," explains Wagner. The innovation allowed users to calibrate the intensity of their lasers, whether they're welding or targeting.

"Today we're doing essentially the same thing," Wagner says. "We use all kinds of camera imagers depending on your wavelength."

For visible lasers, the technology can be smartphone-based, but invisible light requires more specialized equipment. Ophis sources parts from suppliers all over the world to assemble, test, and calibrate its products.

Roundy's Spiricon was acquired by Israel-based Ophir in 2007. "It's very complementary," says Wagner of the match. California-based Newport subsequently bought Ophir in 2012 and let it operate as an autonomous unit, he adds. "Newport's pretty much left us alone because we're doing so good."

The hands-off strategy is paying off. "We've grown tremendously," says Wagner, who came to Ophir in 2007. "We were 17 people when I got here." The staff has since quadrupled, as has the revenue. He credits "innovative products and much better distribution" for the growth, pointing to offices in Utah and Israel as well as Germany and Japan.

Ophir supplies a wide range of customers. "Our biggest market is medical devices, for the devices themselves and the manufacturers of those devices," explains Wagner. Another primary market is military and defense. Weapons sighting and guidance "is all laser-based." Energy and industrial are also markets.

Precision is key for all of Ophir's customers, no matter what they're calibrating. And lasers are becoming more ubiquitous and more powerful, opening up new markets.

New as of 2014, BeamWatch takes a cutting-edge new approach to laser imaging. "We do not have to have the beam on the face of a camera imager," says Wagner. Some lasers are simply too powerful to point directly at most any imager, he adds, but BeamWatch can take a look at a laser sideways to detect its characteristics.

"We affectionately call it, 'Why is the sky blue?'" says Wagner. "The atmosphere is re-radiating the whole spectrum of light. It's like mini rainbows radiating from every particle in the atmosphere, but your eye can see blue better than any other color."

BeamWatch parses through the entire spectrum of visible and invisible light to get a reading on the laser in question and customers are finding a wide range of applications. "It's taking off like wildfire," says Wagner. "We're trying to grow that market by giving them something they've never had before."

Of course, working with more powerful lasers means Ophir needs the latest and greatest technology for R&D in-house, he adds. "We probably have the most powerful laser in the state of Utah at the moment."

Challenges: "Being owned by a public company, you've got to grow every quarter," says Wagner. Logan's size and location also presents challenges for hiring and recruitment, he adds.

Opportunities: BeamWatch is one. More and more powerful lasers in industrial settings represent another. A third is a 3D printing project Ophir is working on with General Electric and several partners. "These guys want to print jet engines and submarine parts," says Wagner. "We're building new equipment specifically for that market."

Needs: "Good engineering talent," says Wagner, calling Logan's Utah State University is a "mismatch” for the company's software-oriented needs.

A bigger building is another need. "We're in the process of looking for more space," says Wagner, noting that the current 18,000-square-foot facility would serve the company better if it were about twice that size.