Custom Microwave

By Eric Peterson / CompanyWeek | Apr 11, 2016

Company Details

Location

Longmont, Colorado

Founded

1965

Ownership Type

Private

Employees

65

Products

Aerospace Components

Longmont, Colorado

Founded: 1965

Privately owned

Employees: 65

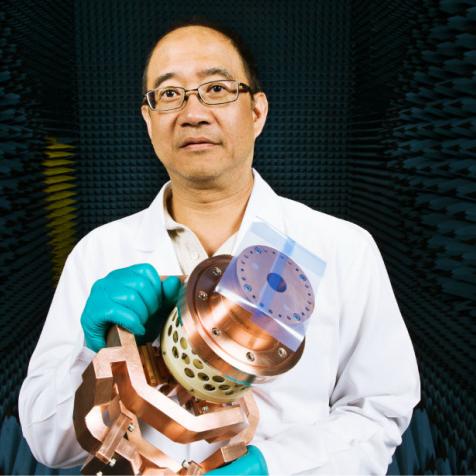

President Clency Lee-Yow has grown the manufacturer of satellite antennas from a job shop to a full-service design-and-build operation.

Founded in Florida by Emory Horvath in 1965, Custom Microwave Inc. (CMi) relocated to Colorado in the early 1970s. The company has called the same block in Longmont home since 1979, graduating from a 5,000-square-foot shop to a 54,000-square-foot facility in the years since.

"We manufacture passive microwave components. We do that for all of the major aerospace companies," says Lee-Yow, reeling off a customer roster highlighted by the likes of Boeing, Lockheed Martin, and Northrop Grumman. "Since 2000, we have supplied hardware for more than 200 satellites."

The company has specialized in feeds -- the structures that transmit and receive signals -- for reflective antennas for government and commercial clients and now is moving into the broader market to design and build entire antenna assemblies.

Feeds aren't all that complicated on the planet's surface, says Lee-Yow, but outer space is a different story. "On the space side, they're fairly complex," he says. "It's supposed to work for 25 years in a very harsh environment."

It first has to survive the launch, then it needs to survive the extreme temperature shifts. It's not just the sun -- or lack thereof. The satellites themselves "are pumping out a huge amount of power," says Lee-Yow. "That translates to heat."

CMi uses electroforming to make many components, and boasts in-house CNC capabilities and thermal and anechoic chambers for testing. "We do all of the manufacturing here and all of the qualification here," says Lee-Yow, touting CMi's testing capabilities as particularly rare. "Even Boeing doesn't have it."

"The reason we're in business is every time they put up a satellite, they want the latest and greatest technology," says Lee-Yow. "We always try to push the envelope."

That means smaller and smaller components with higher and higher performance.

An example: C-Band satellite feeds were about 12 cubic feet when CMi received a request for a smaller design in the mid-'90s. "They said, 'We don't want to fly that monster,'" says Lee-Yow. CMi's engineers came up with a design half that size, then cut it down to a single cubic foot in 2004 that "became a standard," he says.

Another customer wanted to cut weight from a feed in 2012. "We went from something that was 16 pounds to eight pounds," says Lee-Yow. "We find creative ways to fit more in the same space."

As the feeds it makes have gotten smaller, CMi has done exactly the opposite. "I joined the company in 1994 and we were doing $1.3 million," says Lee-Yow. "Last year, we did $22 million."

"The way we did that is adding capabilities," he adds. "Before we were just a job shop." CMi moved into design and manufacturing in 2002 and today "80 percent of the stuff we do is what we design. . . . People expect us to solve their problems."

The goal is to continue to grow with the same strategy of adding capabilities, he adds. "Our mission is to double the size of the company in terms of sales in the next five years."

Challenges: With the growth, operational processes have lagged behind the company's testing and design capabilities, so Lee-Yow turned to Manufacturer's Edge to implement Lean practices and streamline production.

"About a year ago, I said, 'We really need some help -- we can't produce them fast enough,''" he says. "Execution, we were great when we were smaller, but as we've grown it's gotten more difficult."

To continue to grow, "We needed a real fundamental shift," he continues. "You have to look at external changes and drive strategy. Now we're trying to get into not just feeds, but the whole antenna system."

In late 2015, CMi began implementing Lean processes to kick off this strategic pivot. "We're still in the beginning stages," says Lee-Yow. "It's a lot of changes. . . . Manufacturer's Edge has been instrumental in coming up with a road map."

Another challenge is interfacing with the Boeings and Lockheeds of the world. "We have to have all of the same processes of a large company," says Lee-Yow. "They expect us to have the same things they have. We have to be nimble and we have to wear multiple hats."

Opportunities: Europe is a big one. A 1999 decree from the U.S. State Department that classified satellite technology as munitions cut 40 percent of the market for domestic manufacturers. "The U.S. went from 80 percent market share to 40 percent market share," says Lee-Yow. "There were security concerns."

Designing and making entire antenna assemblies is the other big opportunity. Since the aforementioned move into this market in 2015, CMi landed its first contract for an on-ground antenna assembly. Most of the competition is based in Canada or Europe, and the field is dominated by much larger companies.

"In the U.S., there isn't one company that supplies the whole system to the main prime," says Lee-Yow. "We want to fill that void."

Needs: Talent and additional testing equipment to cover the move into providing the entire antenna assembly. "We need people with good experience building the whole system," says Lee-Yow.