Colorado WaterJet

By Eric Peterson | Feb 10, 2015

Company Details

Location

Berthoud, Colorado

Founded

1997

Ownership Type

Private

Employees

7

Products

Water Jet Cutting equipment

Berthoud, Colorado

Founded: 1997

Privately owned

Employees: 7

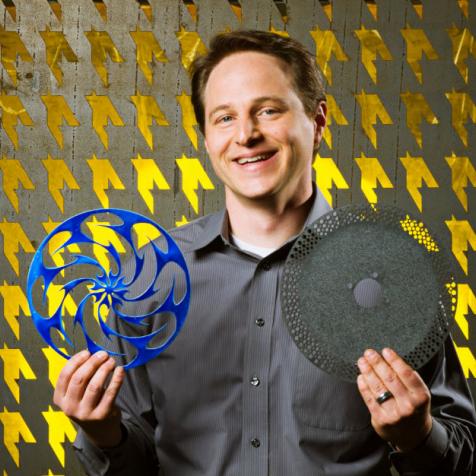

Owner and President Brian Pope's cutting-edge water jets can slice through most any material for markets that range from public art to aerospace.

After working in California as a GM for a photochemical etching company, Pope moved to Colorado when his wife's career led her to CU-Boulder.

He consulted for his former employer and shopped for a small manufacturing operation for a few years before settling on Colorado WaterJet, founded by Hewlett-Packard engineer and water jet hobbyist Dan Nibbelink in 1997. The deal closed in June 2014.

The company is today one of about five water jet shops in the state. Nibbelink "was the first guy to do contract manufacturing with water jets in Colorado," says Pope. "Most waterjet companies have one or maybe two machines. We have three."

The company added the second water jet a decade ago before acquiring a state-of-the art Mach 4C water jet capable of 3D cutting in 2011. "It's about four times the speed of sound," says Pope. "That's 87,000 PSI. It cuts right through anything. We go up to eight inches thick on aluminum and six inches thick on steel."

Colorado WaterJet's bread and butter is cutting blanks of all kinds for machine shops from a wide range of materials, but it also works in ornamental metalwork for signage and architectural features.

The latter market represents about a third of the company's sales, says Pope. Customers have included Chipotle, with thousands of pieces of art metal cut by Colorado WaterJet embedded in the walls at locations coast to coast, and public art programs in Denver, Longmont, and Loveland.

Other contract work ranges from cookie sheets for a local dessert manufacturer and parts for locally made splitboards to displays for Victoria's Secret and titanium components for the aerospace industry.

"Our competition is laser cutters and plasma machines," says Pope, touting water jets' ability to cut through thicker materials without leaving a heat-affected zone on the surface. "We're not deforming material at all. It's basically a sandblasted edge finish."

Pope says a standard turnaround time of five days helps set Colorado WaterJet apart, and that can be cut down to 24 hours with a 35 percent upcharge.

Eight months after buying the business, Pope is upbeat. "It's been good," he says, noting that he's learned a lot in a short period of time. "December and January have been booming."

Challenges: "For me, it's sales and marketing," says Pope. "The technology has been around for a while, but it's not super popular. People don't know the capabilities of it." The solution involves "educating the public that it can be low cost or high precision of everything in between," he adds. "We can put it on 10 different settings."

Opportunities: Pope says he's looking for more repeat business from big machine and welding shops. The company runs one shift now, he adds, so there's plenty of room to grow.

Needs: Employees. Pope says he's looking to hire two new ones in the near term: an estimator with CAD experience and a water jet operator. Skills can be learned on the job. "It's cool technology, but it's very straightforward," says Pope. "You don't have to be a welder or CNC operator."

Pope also says he's looking for more repeat and contract business from machine shops, fabricators, and artists. Potential customers can email sales@coloradowaterjet.com for a quote or additional information.