Company Details

Location

Loveland, Colorado

Founded

2011

Ownership Type

Private

Employees

140

Products

3D printers

www.alephobjects.com / www.lulzbot.com

Loveland, Colorado

Founded: 2011

Employee-owned

Employees: 140

Industry: Electronics & Aerospace

Products: 3D printers

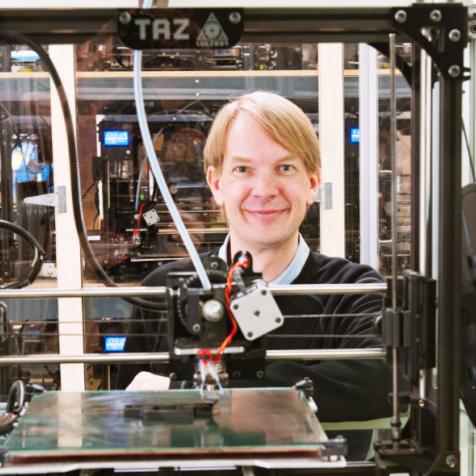

Founder and CEO Jeff Moe has guided his 3D-printer manufacturer to $20 million in sales as the company continues to take the market by storm.

The buzz might have quieted, but 3D printing is no flash in the pan -- particularly when it comes to manufacturing. "The industry continues to develop, and 3D printing continues to be adopted," says Moe.

Aleph Objects has made a name for itself with its LulzBot line of fully assembled 3D printers. Debuting in May 2016, the $2,500 LulzBot TAZ 6 printers feed spools of these material through a "hot end" with a hole the size of a human hair to make a tangible replica, layer by layer, of a digital computer-aided design (CAD) file. Moe touts its size -- "a large desktop printer" -- and improved functionality and ease of use.

It's not just the TAZ 6: 3D printing has become user-friendlier over the years. "It's just gotten a lot easier," Moe says. "I could send you a Mini and you could have it up and running in 15 minutes, 30 minutes. If you can install software, you are three quarters of the way there. It's now accessible to anyone."

Interestingly, Aleph prints its LulzBot printers with LulzBot printers. There are 155 printers that diligently print more than 100 pounds of components daily for the next generation of LulzBots at Aleph's Loveland facility. Then they'll in large part be replaced by their progeny, machines that will also print the components for the next generation. And so on.

Aleph's army of machines have printed more than 2 million parts to date. "Printing 2 million parts prove our machines work," notes Moe.

And the printers get better with every iteration. "There's more sophistication and more automation," says Moe. The TAZ 6's bed auto-levels, the head self-cleans, and the printer is designed for maximum flexibility. "We have a lot more filaments and a lot of new materials," says Moe, reeling off a list that includes silk, bamboo, nylon, polycarbonates, and heat-resistant Ultim.

The market's been loving the ever-better LulzBots. "We've been having huge growth," says Moe. From $1.75 million in 2013, Aleph's sales have snowballed to $4.6 million in 2014, $15 million in 2015, and $21.1 million in 2016. The company ranked 122nd on the 2016 Inc. 5000, second-best in Colorado and tops nationally for privately held hardware manufacturers. The staff has grown from about 20 employees in 2013 to 140 today.

Moe has a conservative forecast for 2017: "This year, we're going to be in the $20 million range." And that follows a pattern. "The growth isn't linear," he says. "You grow and you plateau. You grow and you plateau."

In late 2013, the company moved into its current 17,000-square-foot building, a former Elmore James plant Moe bought with his brother. The growth demanded more space as manufacturing operations have overwhelmed the company's 17,000-square-foot facility in Loveland, so the sales, marketing, and tech support offices have relocated to a 6,500-square-foot building near Lake Loveland.

And more space means more hires. Salespeople are a focus. "We think that's going to bump us up to a new level" -- to annual sales of $50 million, maybe $100 million.

The company's business is split between the "prosumer," industrial, and educational markets. "We sell to all these large Fortune 500 companies and government agencies and NASA," says Moe. "We've established a heck of a good list of premium customers. This who's who of a client roster includes the FBI, Los Alamos National Labs, Harvard University, Caterpillar, and Google.

Corporate customers use it to both prototype and manufacture. Numerous companies use it as a cornerstone of manufacturing operations, including MotoMinded in Colorado Springs, with six -- and counting -- LulzBots cranking out motorcycling accessories. Minnesota-based Verterra Energy is utilizing a LulzBot to prototype its hydropower turbines.

The educational market has likewise boomed. "It's been a really big hit in schools and libraries," says Moe. "The teachers love it, the students love it, the parents love it, the administrators love it."

Aleph has shipped to customers in 85 countries to date, and about 20 percent of the company's sales are exports.

Moe's background as the founder of a Colorado ISP, Verinet Communications, led him into the world of open-source software, then into open-source hardware and 3D printing. To this end, all of Aleph Objects' technology is all open source. Plans, CAD files, and assembly instructions are publicly available on the company's website.

And it helps drive continuous innovation. "We're working on developing new machines," says Moe. "We have a current prototype that prints larger parts." Engineers are also developing new tool heads, including a high-speed head, and models that can print electronics.

Perhaps best of all, every LulzBot printer is shipped with a plastic octopus that it printed as a last quality-control check. "It's the last piece that gets printed, and the company gets something that was printed on their machine since day one," he says. "It's on our logo and it's an awesome animal."

Unsurprisingly, Aleph has even innovated on the octopus. The Rocktopus -- featuring fingered hands making the rock 'n’ roll devil's horns salute -- has become the company's mascot. "We did a huge one for CES," laughs Moe. "It was three or four feet across."

Challenges: "We'll be getting set up and adding new employees in the new building," says Moe. He expects to make at least 10 hires by the end of 2017.

Keeping on the leading edge is also a challenge. "As a high-tech company, we always have to be developing new products."

Opportunities: The educational market is a big one, but Moe says he also expects more sales to other manufacturers. "There are going to be more parts made with 3D printers."

Needs: While Aleph just closed on a $3 million line of credit, Moe says he is pursuing "tens of millions of dollars" of venture capital with a target closing date before the end of 2017

When he founded the company, Moe wasn't so sure he could balance the open-source model with outside investment, but he's since changed his tune. "We've shown that it is possible to be a growing open-source hardware company and make money," he explains. "That is what investors are ultimately interested in."